MC-L2

Inline laminator for added durability and security

Increasing card longevity and security

The MC-L2 laminator module is the ideal solution to enhance the durability and the security of cards printed on the MC310 direct to card printer or XID-M retransfer printer series. Easy to install and operate, the MC-L2 works inline to laminate cards at exceptional speeds, laminating both sides of the card in less than 20 seconds thanks to the simultaneous dual-side lamination process.

The MC-L2 can be easily connected to the MC310 using a connection plinth, which also serves as a useful lockable storage unit for cards and cleaning kits.

The MC-L2 is available in three different configurations to suit any card lamination application:

• Single-sided lower cassette only

• Single-sided upper cassette only

• Dual-sided with both lower and upper cassettes

Key strengths

Ideal for

- National ID cards

- Driving licenses

- Resident cards

- Corporate cards

- Campus / student cards

Options

- Continuous overlay film or patch laminate

- Standard or customized holographic or

clear laminate - Single-sided (upper or lower cassette) or

dual-sided lamination - Front cover lock

Enhancing card security

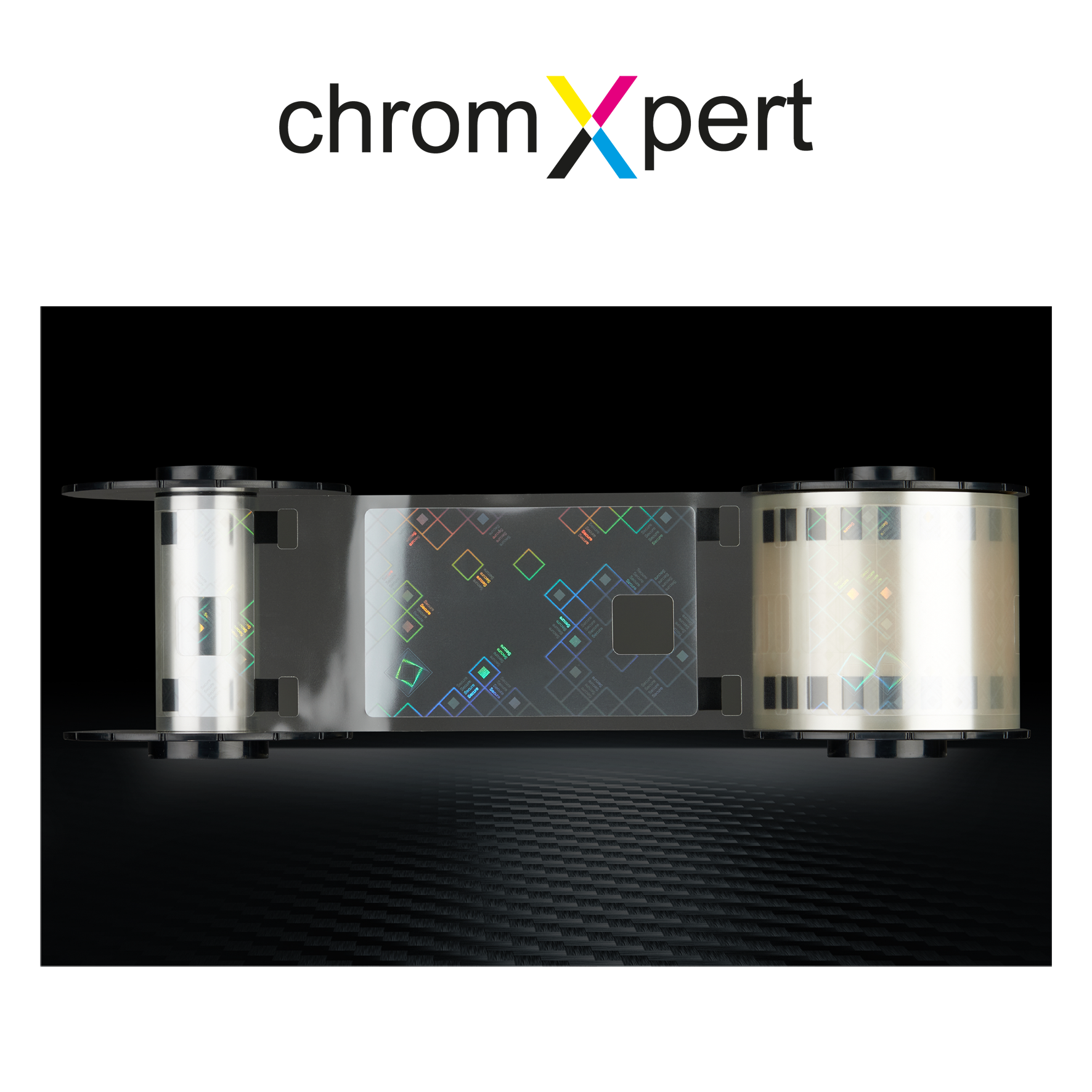

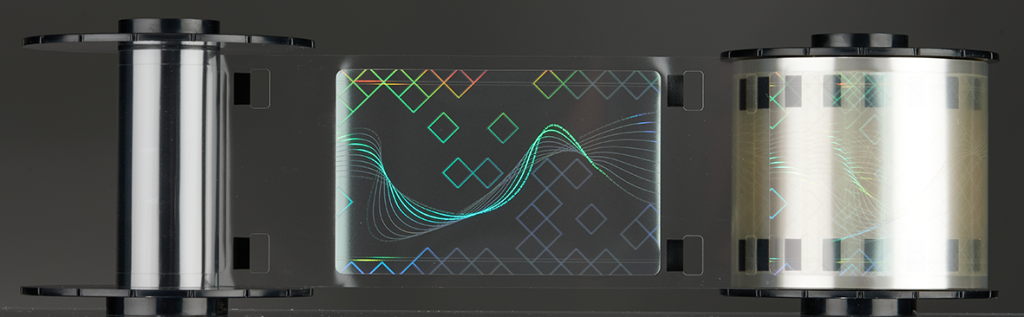

Once personalized by the printer, cards can be laminated with the MC-L2 by using a heat-sealing film. This film can contain holographic and other Visual Security Elements (VSEs) for enhanced protection. Matica offers a range of standard holographic designs in both patch laminate and continuous film formats. For the ultimate security protection, organisations can opt for a customized holographic laminate with VSEs that are unique to them – this approach is often adopted for government secure documents such as driving licenses and national ID cards.

Reinforcing card durability

Another important reason to laminate pre-personalized cards is to increase the durability and extend the life of the card, thanks to the enhanced mechanical and UV resistance of the lamination material. A card laminated with a 1.0 mil (35 micron) patch can have a lifecycle of up to 10 years – a timeframe often mandated for government/citizen ID schemes.

Product features

Technical specifications

Lamination

Lamination method

Heater roller

Lamination mode

Single and dual-sided

Halogen lamp

Single: 500W x 1 vertical

Dual: 500W x 2 vertical

Lamination speed

19 seconds

Laminates

Security

Protected with RFID tag

Thin film overlay

Clear or standard/customized holographic 1000 repeats/roll

Patch

Clear or standard/customized holographic 500 repeats/roll

Patch thickness

0.5 mil (clear)

0.6 mil (holographic)

1.0 mil (clear/holographic)

Cards

Card materials

PVC, PET-G, PET, ABS, PC

Card format

ISO CR-80-ISO 7810

53.98 x 85.60 mm

(3.375” x 2.125”)

Card thickness

0.76 -1.0 mm

(30 – 40 mil)

Capacity

Output stacker: 150 cards

Manual single card feed or inline with MC310 or XID-M series printers

Connectivity

Connectivity

USB 2.0 (High-speed)

RS232

Platform

Printer dimensions (L x W x H)

320 x 214.1 x 320.1 mm

(12.5″ x 8.4″ x 12.6″)

Weight

10kg

(22lbs)